A1 Professional Asphalt & Sealing Llc Fundamentals Explained

A1 Professional Asphalt & Sealing Llc Fundamentals Explained

Blog Article

The Definitive Guide to A1 Professional Asphalt & Sealing Llc

Table of ContentsSome Known Details About A1 Professional Asphalt & Sealing Llc The A1 Professional Asphalt & Sealing Llc PDFsLittle Known Questions About A1 Professional Asphalt & Sealing Llc.Indicators on A1 Professional Asphalt & Sealing Llc You Should KnowA1 Professional Asphalt & Sealing Llc Fundamentals Explained

They also make it possible for the opportunity of area test and get rid of the opportunity of sampling mistakes where the asphalt being used was not the very same as obtained by the testing laboratory. Simon Hesp, Queens College (Kingston, Ontario) The TFHRC team will soon submit to AASHTO the draft test methods that transportation companies can utilize to evaluate for the existence of REOB in asphalt blends.is a senior study drug store on the Sidewalk Products Team in FHWA's Office of Framework Study and Advancement and Federal laboratory manager for the chemistry lab at TFHRC. He is an other of the Royal Culture of Chemistry in the UK and a Chartered Drug store. For even more information, contact Terence Arnold at 2024933305 or .

Crack loading is when warm sealant is used to fill up cracks in pavement to stop water from doing any longer damages. The sealant will certainly abide by the asphalt, keeping water and various other natural environments from penetrating and exploiting the weak point in your pavement. Among the most significant mistakes people make when it concerns cracks in their pavement, is waiting too long to get them loaded.

Getting The A1 Professional Asphalt & Sealing Llc To Work

Sealcoating leaves your sidewalk looking smooth and dark. This is the perfect option if you are looking for a simple means to improve the look of your asphalt and shield it from the elements. Prolongs life of pavement Speeds up the melting of snow and ice Decreases lengthy term repair service prices Safeguards pavement from oxidation, oil, chemical spills and water infiltration Boosts appearance of property Milling is the process of eliminating the leading layer of asphalt without interrupting the underlying subbase.

Milling can be completed at a fraction of the price of a full restoration due to the fact that just the top layer is eliminated and changed. https://www.pubpub.org/user/john-tally. The entire process can be finished in a relatively short time period. Expense reliable Rapid job conclusion Recycling of old material Patching is the process of filling out fractures

A1 Professional Asphalt & Sealing Llc Things To Know Before You Buy

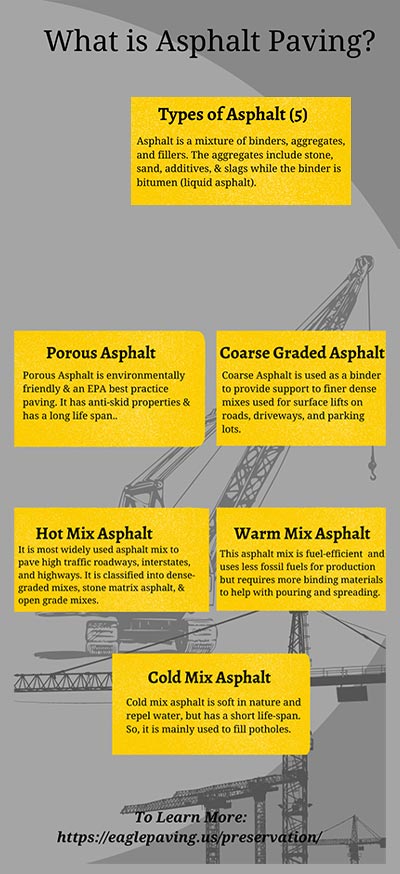

All particles has to be gotten rid of, periodically there might also be plant poking through which need to be thrown away from the root. cold mix vs hot mix asphalt. Asphalt requires a strong base, otherwise, you'll simply have a lot more issues in the future. The type of asphalt used to load pits will rely on the weather condition and size of the pit, normally warm or cool mix asphalt will be made use of

Relying on the dimension of the split, various machinery or devices can be used for this. An you could try here asphalt overlay can be assumed of as a big patching work over a stretch of asphalt. Overlay is normally used when existing asphalt is revealing some indications of cracking and holes, yet not quite adequate damages to require a full substitute.

The below base is the bottom the majority of layer, it will be sustaining your brand-new sidewalk. The binder layer is a large aggregate mixed with oil, that makes it strong and durable. As soon as this action is done it's time for a proof roll. A proof roll is a test to ensure the underlying surface area is strong enough to support the new asphalt.

Some Known Incorrect Statements About A1 Professional Asphalt & Sealing Llc

It's never too late to find out something new, and when it pertains to asphalt pavement installation, there are several points that home owners, industrial property proprietors, and town employees might not know. At Wolf Paving, we are Milwaukee, Oconomowoc and Madison asphalt paving professionals in who take pride in enlightening people concerning whatever asphalt it's our enthusiasm.

The primary step in the asphalt setup process is to get rid of the existing surface, whether it is asphalt, concrete or pavers. Demolition and elimination is finished utilizing hefty machinery, consisting of little bobcats and forklifts and when required, front loaders and huge dump trucks. Particles is then removed. At Wolf Paving, we recycle the old asphalt and concrete in our asphalt plants, transforming degrading waste into solid, usable brand-new asphalt.

The sub base provides a stable surface to sustain new sidewalk. If the below base is not suitably compressed, the asphalt surface area on top will certainly not supply years of sturdiness.

How A1 Professional Asphalt & Sealing Llc can Save You Time, Stress, and Money.

Wolf Paving has also spearheaded a new process called plowing. This procedure involves damaging the sub base, but rather of eliminating every one of the soft clay and dirt, it is instead combined with added accumulation to enhance the stamina of the compromised locations - what is cold mix asphalt. Once the sub base is laid and any kind of soft areas are recognized and fixed, it is time to add the binder

Report this page